Design & Engineering Services

Making Essential Decisions to Ensure Accuracy and Success

Design and Engineering Services at Century-Tywood

At Century-Tywood, sheet metal design and engineering is the building block that determines each material, machining process, dimensions, and tolerancing. A design’s accuracy is essential to creating precise parts that are suitable for your intended application. We have understood this from our early days, even before the advent of CadCam systems, and we continue to emphasize our engineering approach with every part we produce.

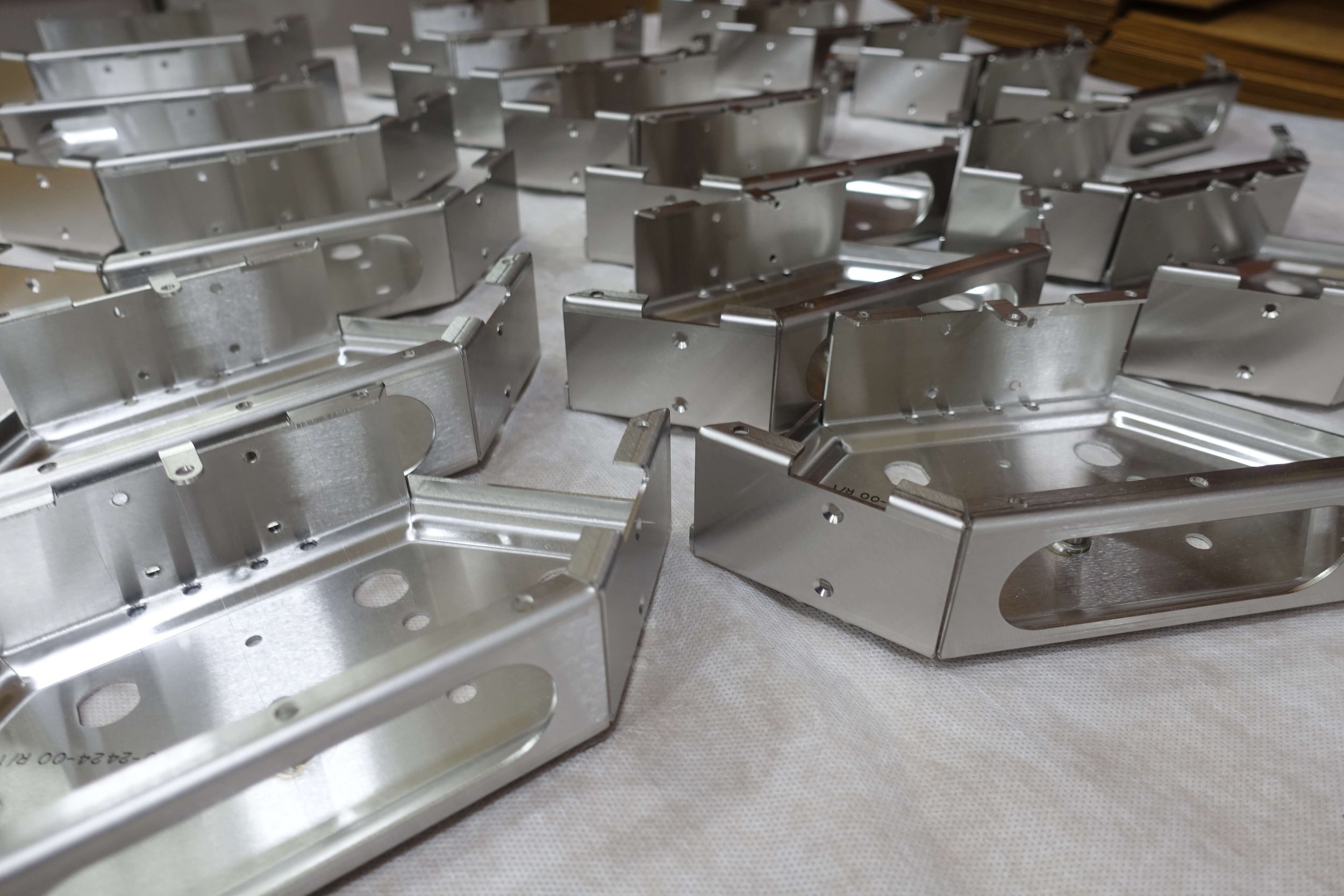

Precision Machined Components, from Design to Concept

Century-Tywood has honed our Design for Manufacturing (DFM) processes to provide the best results for our customers. From the moment we receive a part to the time we send an order for delivery, our engineering and production teams work strategically to follow customer specifications and exceed expectations

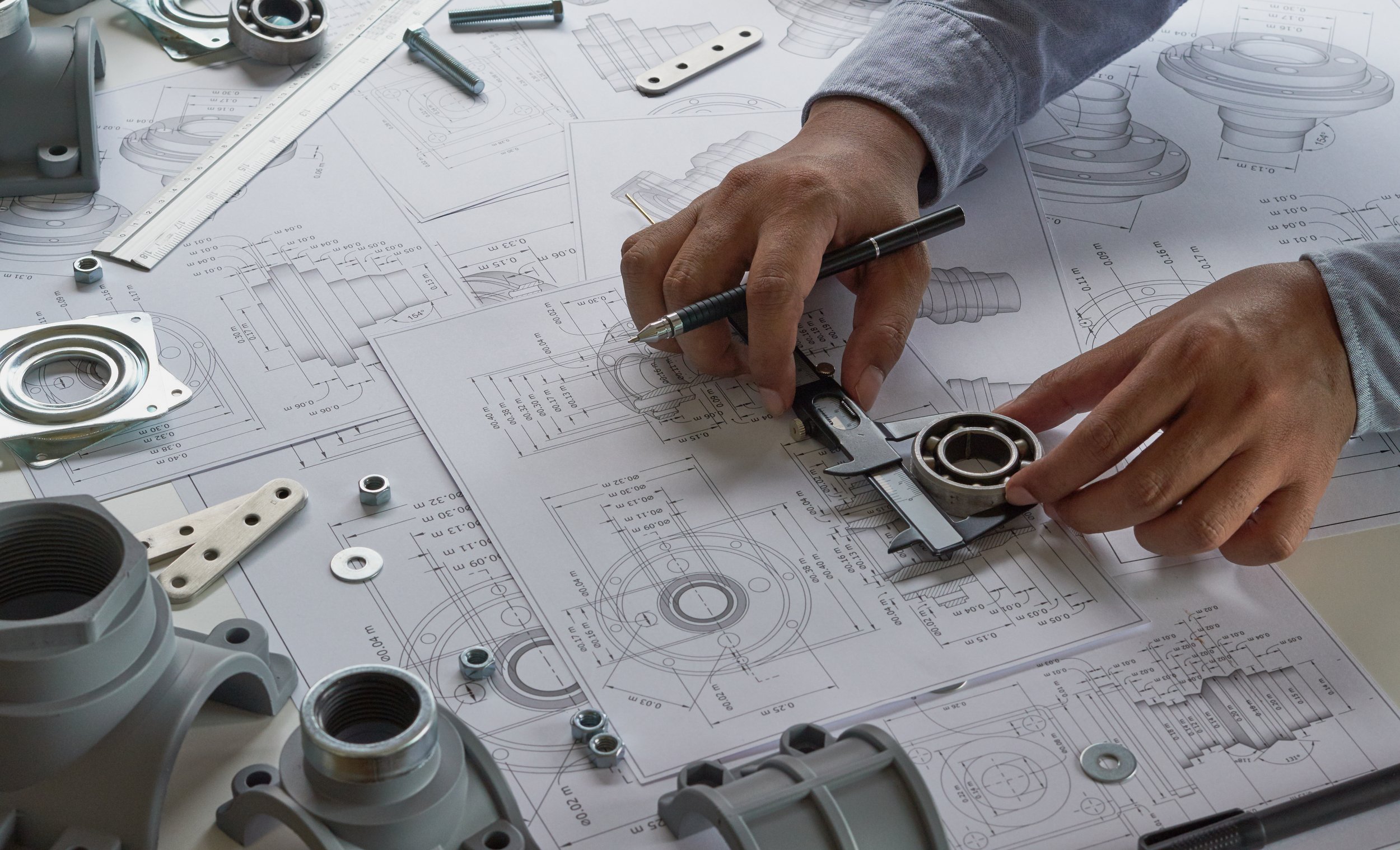

Design Stage

Our engineers prefer to work with native files from design programs such as Solidworks, where we can review how an individual product or multi-part assembly can be manufactured with the most efficient and cost effective methodology. However, other file formats are also helpful, such as DXF.

When files are not available, working from revision controlled drawings can still get quality results but it requires more manpower on our end. For the most efficient processing of jobs from quote to dock, we suggest that you provide us with detailed electronic files and models. This will always produce the most reliable, cost-effective processes with the short lead times our customers look for.

Production Stage

Once we receive a quote request, we typically deploy the same approach each time.

First, we look at the manufacturability of a part and seek out ways we can make adjustments to parts that would save time and money in the operation and ultimately to the customer.

Century-Tywood puts an emphasis on investing in the latest technology from quoting and engineering to the shop floor, and our technology is moving us closer and closer to automating our upfront processes. Our goal is to always make the most repeatedly consistent product and to build products where quality can be designed into the part and the process.

This leads to the next step in our process, in which we work with our customers to educate them on the fastest and most efficient methods needed to get the job done on time and on budget. Our engineering experts are always available to review your products and see how we might be able to improve reliability and reduce costs both through engineering and production efficiency.

When you’re ready to reach your goals and production demands, contact us to see how our sheet metal design and engineering team can support you.