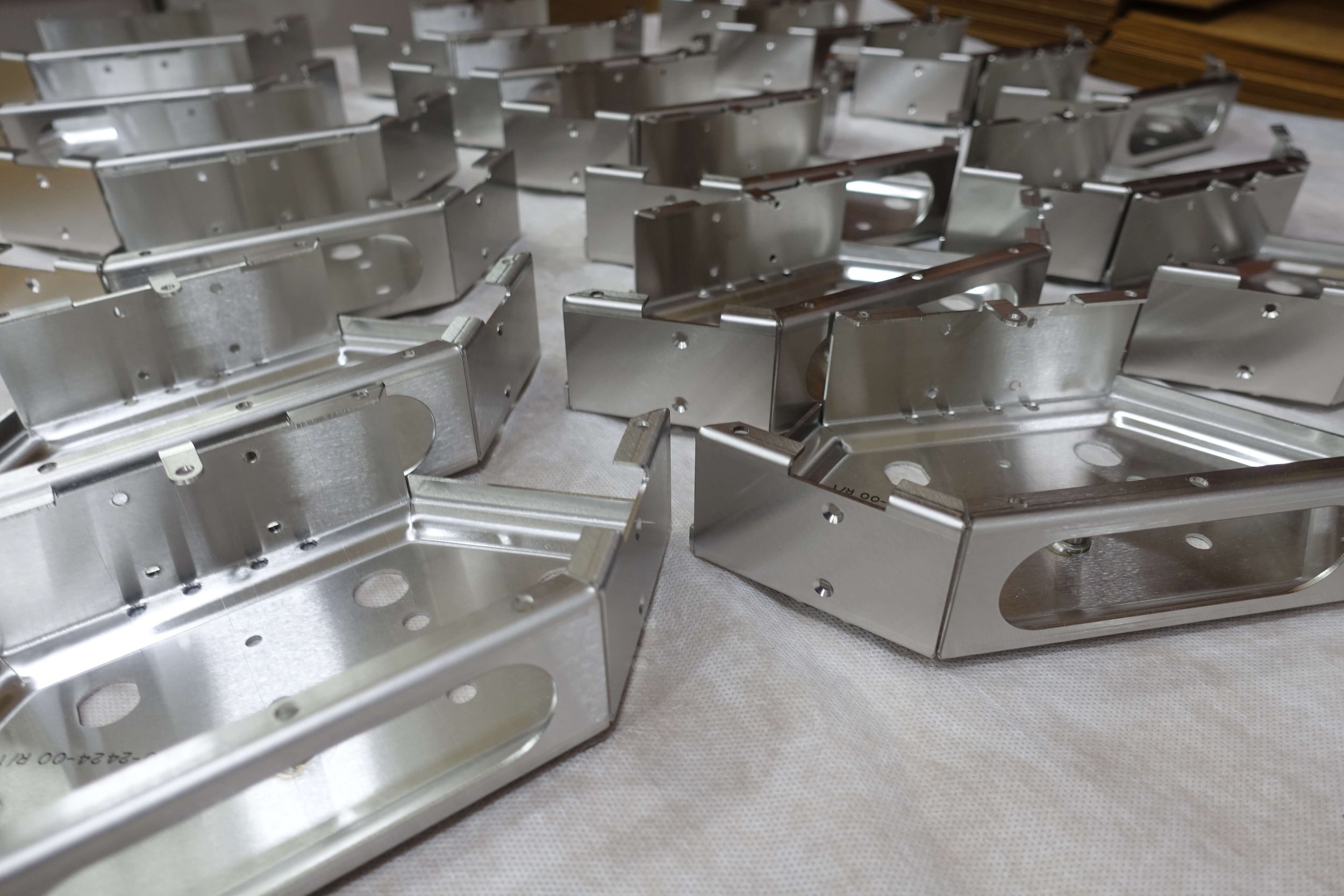

Specialty Metal Fabrication Services

Extensive Experience with a Variety of Metals

Specialty Metal Fabrication at Century-Tywood

At Century-Tywood, we work closely with a variety of materials. Our experience has provided us with a breadth of knowledge on best practices of machining components from different metals. No matter the application or industry, we can offer recommendations on what metals to use.

Titanium Fabrication

Titanium is an extremely strong metal with a low density and high melting point. These factors make titanium a choice material for a range of applications, especially in the aerospace industry. Additionally, as a highly biocompatible metal, titanium is commonly used in the medical industry.

While producing precision machined components from titanium, there are a few considerations we consider. Most prominently, titanium is a highly reactive metal, so it needs to be closely monitored during various stages of the manufacturing process. Century-Tywood has extensive experience working with specialty metals, so we are a choice precision sheet metal fabricator for parts made from titanium and other specialty alloys.

Copper Fabrication

Copper is a highly malleable material with high electrical conductivity. While steel and stainless are used more often for structural integrity and strength, copper has vastly different use cases.

Expertise

Proper custom sheet metal fabrication of copper products requires skills and knowledge developed over years of experience. Here are some of the considerations we make when working with copper:

Copper cannot be cut on traditional CO2 lasers the way stainless, cold rolled steel, and aluminum can.

Copper is a soft metal that requires the right knowledge for forming detailed radii, especially when used for springs and gaskets.

Hardening and finishing processes need to be closely monitored based on special requirements to ensure the part is machined to customer specifications.

Handling

Copper is a soft metal, so it is easily nicked or scratched. Small imperfections might not be noticeable in a part’s original state, but they might show up after finishes have been applied. That’s why handling is one of the most important details we pay close attention to while fabricating copper parts.

Soldering

Century-Tywood has developed a skilled soldering team that helps us produce thousands of copper assemblies each month. Similar to welding in its application, soldering fuses copper assemblies into one piece using silver rod. This process requires meticulous detail to safeguard against pinholes and other defects caused by imperfections in the material.

Thin gauge copper forming and soldering can present challenges during the fabrication process. A precision sheet metal fabricator needs to put a great deal of thought put into the process in order to meet unique customer specifications. From small and simple parts to large and complex arrays, Century-Tywood has the ability to meet most copper production and soldering needs.