Progressive Tool Design and Die Making

Developing Tools and Dies since 1947

Tool Design and Die Making at Century-Tywood

While we have become one of the leading suppliers of sheet metal fabrication services in New England, Century-Tywood also offers significant capabilities in tool and die making.

Even as technologies change and the need for traditional stamping has shifted to other modalities, Century-Tywood has maintained a staff of highly experienced machinists and tool makers. In turn, we offer our customers the flexibility to move from short-run prototypes to large-run stampings without missing a beat, with the knowledge that control of the entire process is right next door.

As with many other manufacturing processes, much of the precision metal stamping done today has moved overseas. This ultimately leads to major disruptions to delivery when uncertainties arise. We offer our customers stability in production with the knowledge that our team of tooling experts can take complex designs and turn them into simple solutions. And our vast knowledge of tool and die design and manufacturing all happens right here in New England.

The Benefits of Progressive Tool and Die Making

Any tool maker worth his salt understands the benefits of progressive tooling, as well as the cost savings it can pass on throughout the lifecycle of a product. Century-Tywood has been developing progressive tools and dies since 1947 and has passed this knowledge onto our team of tool and die makers, as well as our engineering team.

Here’s how our tool making expertise directly benefits our customers:

Best Path to Production

Our team’s expertise allows us to develop a manufacturing plan based on producing the best possible results for our customers needing production quantities.

Greater Precision

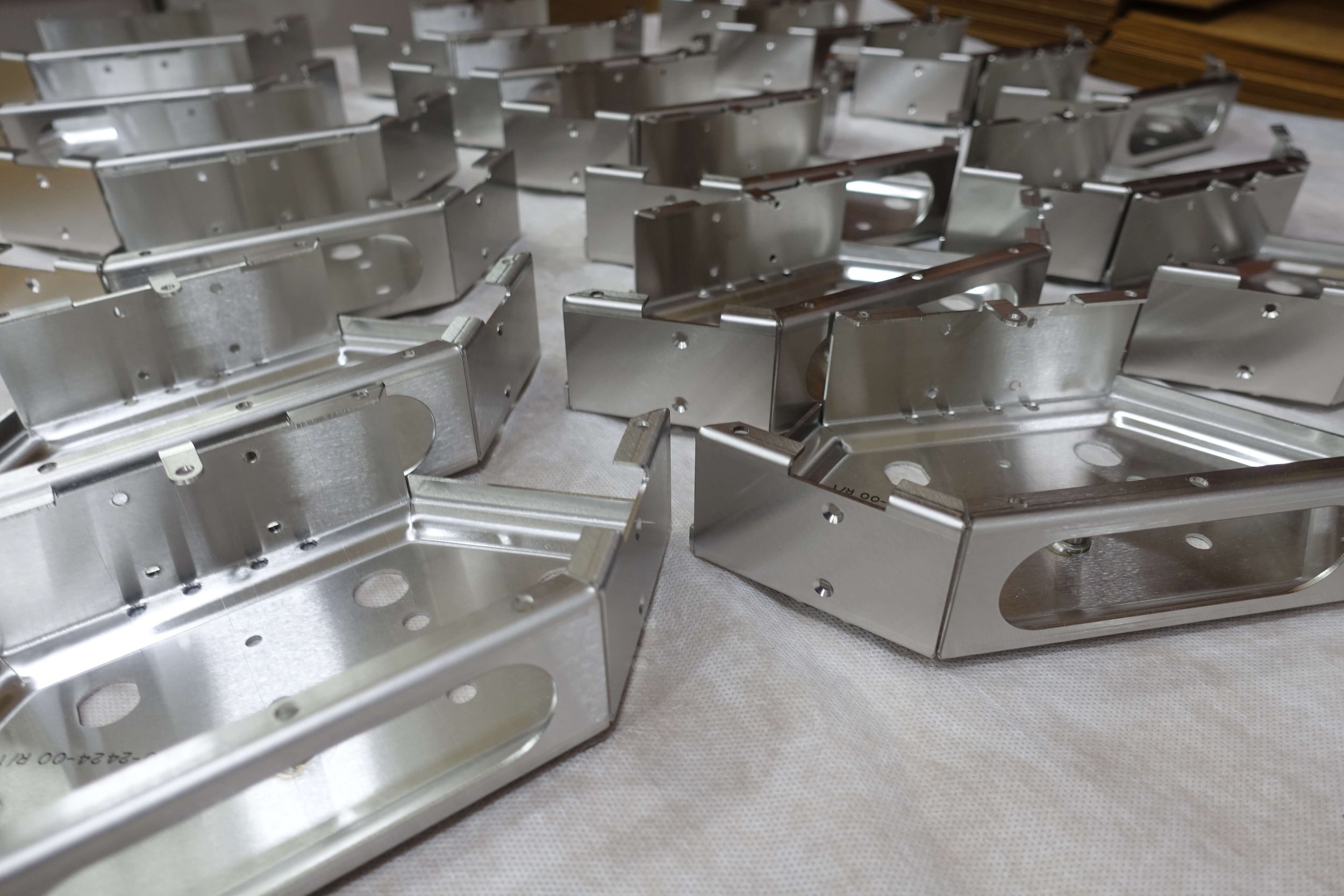

Through progressive tooling processes, we can produce highly repeatable components with extremely close tolerances.

Shorter Lead Times

Since we have a wide array of capabilities from precision metal stamping to custom sheet metal fabrication and machining, we can determine the best path to production in a short amount of time, saving our customers precious time to market.

Cost Savings

Using progressive tooling processes (rather than fabricating the component all the way through) drops the unit price dramatically. Progressive tooling results in quicker setups and produces less scrap, meaning less overhead that we build into our billing.

HVAC Corner Brackets

Century-Tywood offers a variety of off-the-shelf HVAC corner brackets, which we can ship on demand. All of our products are compatible with all major manufacturers’ duct fabrication equipment.

Our patented #3 and #6 Gator Grip corners are not your ordinary corners; they save our customers both valuable assembly time and money with their value-adding features:

30% faster installation, which effectively reduces costs

Improving holding power

No unnecessary damage to ductwork

Compatible with all major manufacturers

Our Gator Grip corners are the #1 quality bracket on the market. Because we deeply believe in the quality and value of our product, we are offering a free sample to customers willing to give it a try. For more information, contact us.