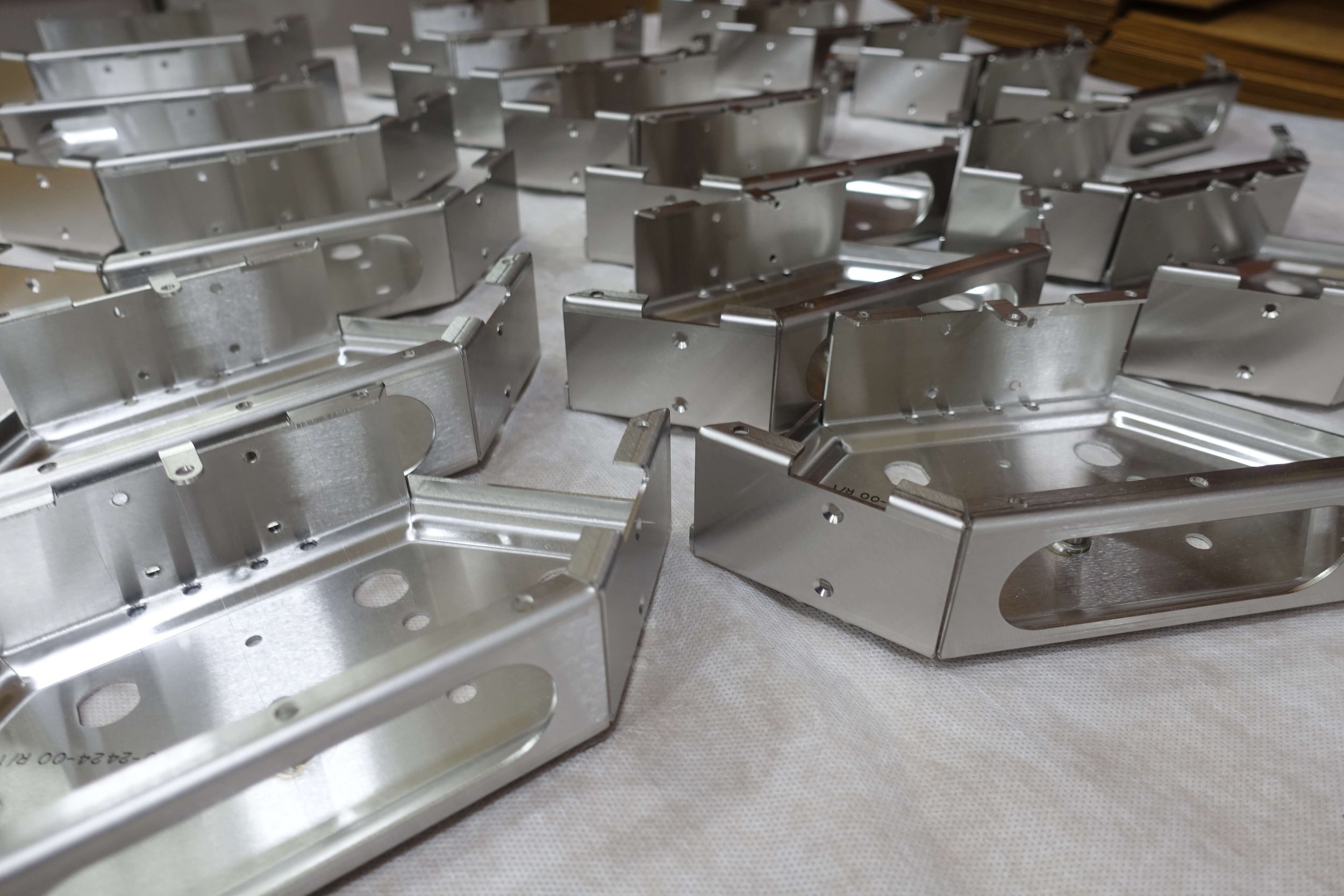

Precision Metal Stamping

Delivering a Wide Range of High-Quality Stamping Services

Sheet Metal Stamping at Century-Tywood

Long before we became experts in precision metal fabrication, Century-Tywood was a well established metal stamping house, providing quality precision metal stamping to businesses across the New England region.

Today, with close to a dozen machines in operation, our metal stamping operation is still an integral part of Century-Tywood and a synergistic complement to our sheet metal fabrication services. We have great flexibility in how we can approach projects, using the best of both worlds to deliver the highest value to our customers.

Metal Stamping Capabilities

Century-Tywood has a wide-ranging capacity in metal stamping operations from blanking and embossing to bending and notching.

Our stamping capabilities allow us to augment our manufacturing operations with cost-effective options for small- to medium-sized parts in the production process. We can punch parts in as little as a single hit.

Size Capacity

With machines running from 20 to 80 tons, our largest press has a part capacity up to 12″ x 18″ and 80 tons of punching power.

Embossing Services

Century-Tywood can handle challenging processes such as embossing features on larger parts. When an embossing operation requires a tool that is too large for the turret presses, we can create these tools for the punch press instead. This creates flexibility within the process that balances out of production and reduces bottlenecks in critical operations such as press brake forming.

Multiple Operations

In other cases, we have parts where a progressive die allows us to not only punch the part but also form the item in the punch press during the same setup. This type of tool takes us from raw coil stock to a completed part in one operation, resulting in significant cost savings for our customers.

Prototype to Production

Quantities are always a consideration, as hard tools need to be manufactured for production runs. In these instances, our custom sheet metal fabrication capabilities allow us to run small quantities without the high cost of tooling. As production ramps up, we are then able to seamlessly move to a hard tooling operation on a punch press, helping reduce costs as manufacturing demand increases.

When your project needs precision metal stamping operations, don’t hesitate to contact us with any questions you may have or request a quote to get started.