Lean Manufacturing at Century-Tywood

Committed to Continuous Improvement

Our Investment in Lean Manufacturing

In the world of high tech sheet metal, demands on manufacturers have changed dramatically over the years. Gone are the days of large volume purchases. Meanwhile, demand for quick turn deliveries has increased considerably. The shift has resulted in new challenges to product delivery in a fast-changing environment and the need to ensure consistent product quality under all circumstances.

In order to tackle these challenges, Century-Tywood Manufacturing took a different approach and shifted into Lean Manufacturing.

As a high mix, low volume manufacturer of sheet metal and precision machined components, we decided to make significant investments in our people and processes. In 2017, Century-Tywood was awarded a Workforce Training Grant by the state of Massachusetts for the implementation of Lean Manufacturing into our operation.

Our goal was to create a world-class manufacturing facility that could compete anywhere in the world, a big goal and challenging opportunity. We committed our workforce to over 6,000 hours of training, redesigned our manufacturing process, and made significant investments in new equipment during the grant, which has benefited our customers greatly.

Our ongoing Lean programs help us to continuously improve our operation and have provided major benefits to our customers in the following areas:

Our top-notch quality system

On-time delivery

Quick turn production through our flexible manufacturing cells

Less inventory exposure of large production runs

Cellular Manufacturing

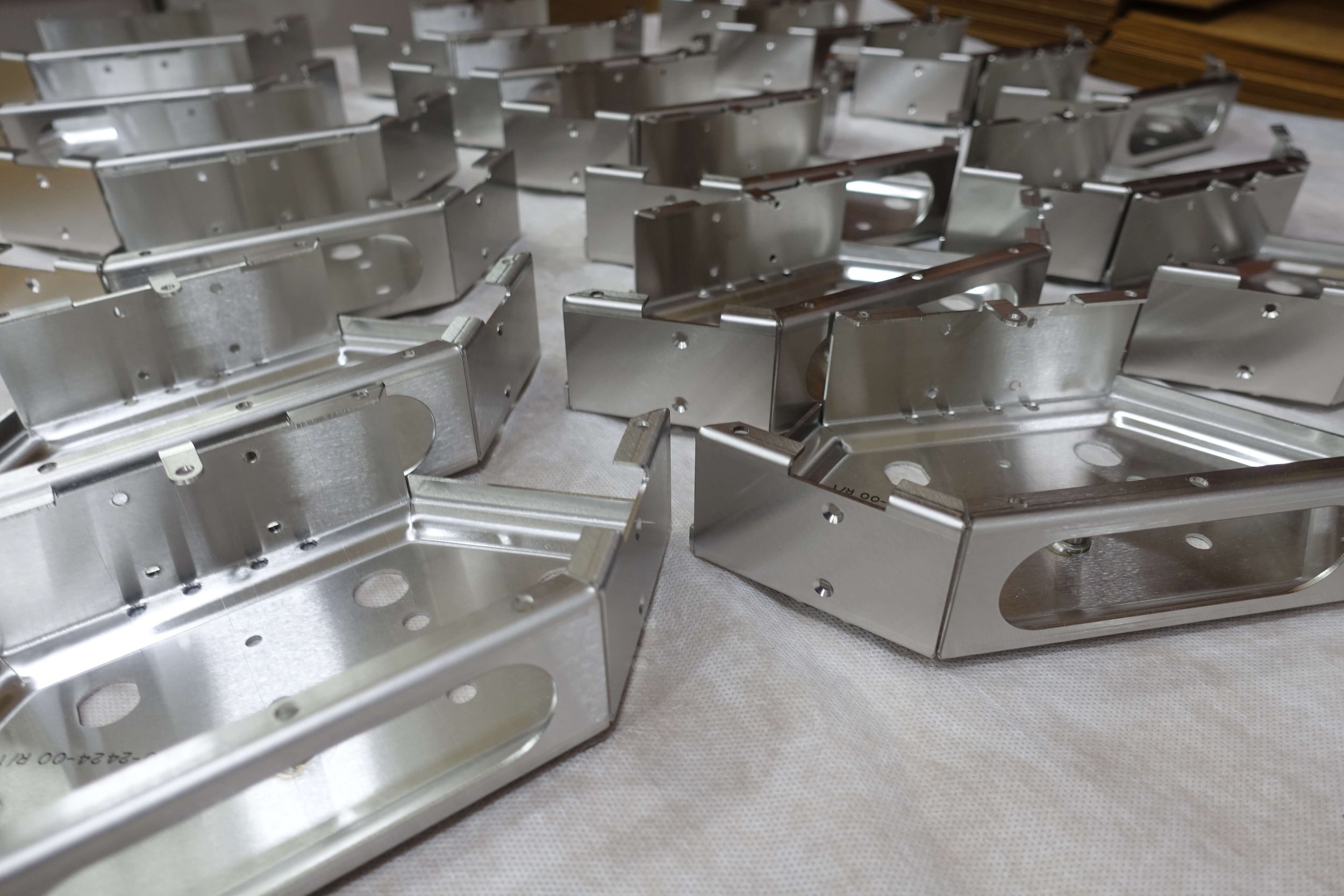

Traditionally, sheet metal fabricators make production runs in large batches. This spells trouble for manufacturers when demands change quickly and deliveries need to be pulled in or pushed out. Shop layouts focused on moving large batches from one workcenter to another create issues with excess travel, quality, and overproduction, all of which are considered waste in a Lean system.

In order to meet demands more effectively, we looked at every step of our operation to see where dramatic changes in our layout and processes could impact our ability to be more flexible and drive efficiencies. The result was a completely redesigned shop layout with Flexible Manufacturing Cells with cross-trained teams focused on reducing both machine setup time and product cycle times.

By co-locating traditional workcenters within a Manufacturing Cell, we have been able to make dramatic improvements to our flexibility. This has resulted in numerous benefits for our customers and helped us create a roadmap for future success that drives value back to our customer.

JIT and Kanban Programs

Just-in-time manufacturing and Kanban programs are key components of Lean manufacturing and flexible Cellular Manufacturing. From vendor delivery programs for raw stock to customer Kanban programs, Century-Tywood strives to create a complete system from start to finish.

We work with our customers to create the best possible manufacturing plans from prototype through the changing dynamics of product life cycles. The best manufacturing plans start with Design for Manufacture and continue with our Design for Production planning where we analyze product demand, manufacturing best practice, and specific cell capabilities to ensure part placement and project production in the most efficient and flexible environment.

This process…

Empowers us to meet customer demands

Allows us to adjust programs when needed

Produces the most consistent, on-time delivery schedules

Provides maximum flexibility for increases in manufacturing quantities

Reduces potential exposure from an overproduction of inventory